We produce a wide variety of pipe parts mainly for automobile exhausts and can offer in-house production that includes bending, diameter adjustment, cutting, welding and other processes. We are also actively integrating automation and process transit systems to our production line while working daily to achieve higher manufacturing quality and efficiency.

Robot 1R/B+2Positioner 1 Axis Laser welding (LW) is a technique for joining metals using a laser beam. The welding is achieved by heating the area and the applying pressure. It is the most suitable welding method for thinner, high-strength, wear-resistant steels.

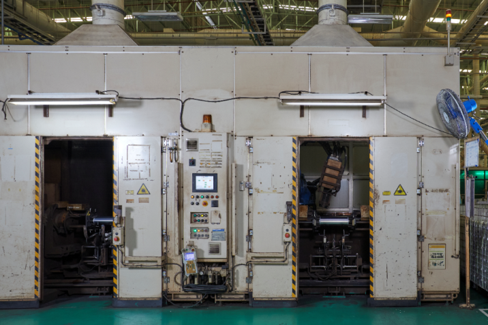

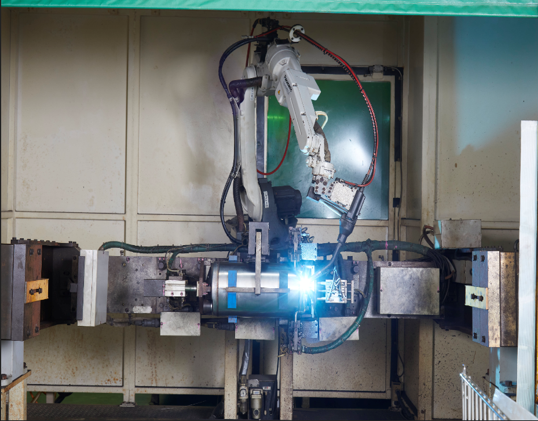

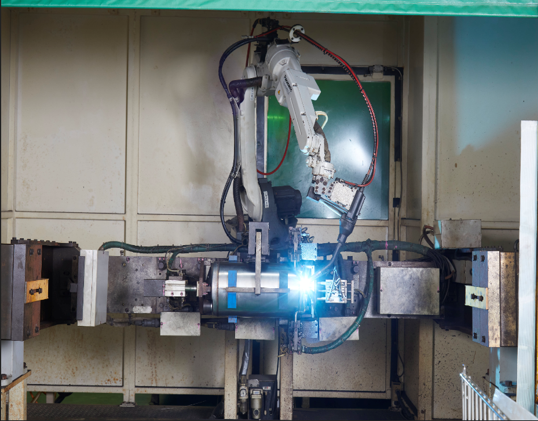

Robot 1R/B+2 Positioner 2 Axis 6 Axis Articulated Arc Welding Robot High speed welding and ultra low spatter over a wider current range TAWERS minimize spatter generation even with steep push / trial torch angle High quality welding of thin material, with exceptionally good penetration High quality CO2 welding. 98% less spatter generation at 200 A 99% spatter reduction by MAG welding at 250 A

Robot 1R/B+1Positioner 1 Axis 6 Axis Articulated Arc Welding Robot High speed welding and ultra low spatter over a wider current range TAWERS minimize spatter generation even with steep push / trial torch angle High quality welding of thin material, with exceptionally good penetration High quality CO2 welding. 98% less spatter generation at 200 A 99% spatter reduction by MAG welding at 250 A

Robot 1R/B+1Positioner 1 Axis 6 Axis Articulated Arc Welding Robot High speed welding and ultra low spatter over a wider current range TAWERS minimize spatter generation even with steep push / trial torch angle High quality welding of thin material, with exceptionally good penetration High quality CO2 welding. 98% less spatter generation at 200 A 99% spatter reduction by MAG welding at 250 A

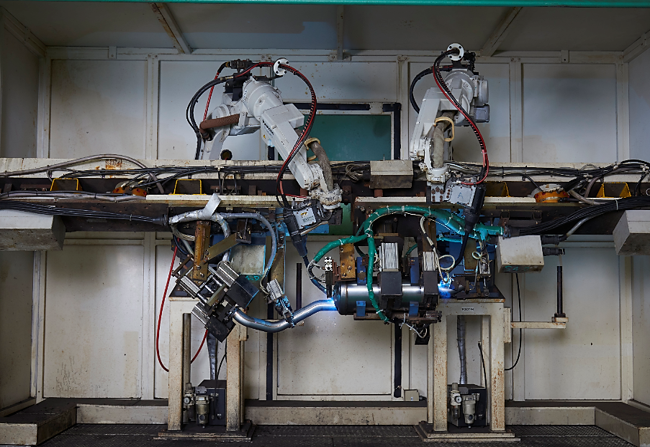

Robot 2R/B+1Positioner 1 Axis 6 Axis Articulated Arc Welding Robot High speed welding and ultra low spatter over a wider current range TAWERS minimize spatter generation even with steep push / trial torch angle High quality welding of thin material, with exceptionally good penetration High quality CO2 welding. 98% less spatter generation at 200 A 99% spatter reduction by MAG welding at 250 A

water leak detection system is a system that monitors its environment for any water leaks or spills via probes or sensing cables that could go unnoticed. They would generally activate an alarm to alert the engineering team of an issue and to allow them to respond quickly and efficiently

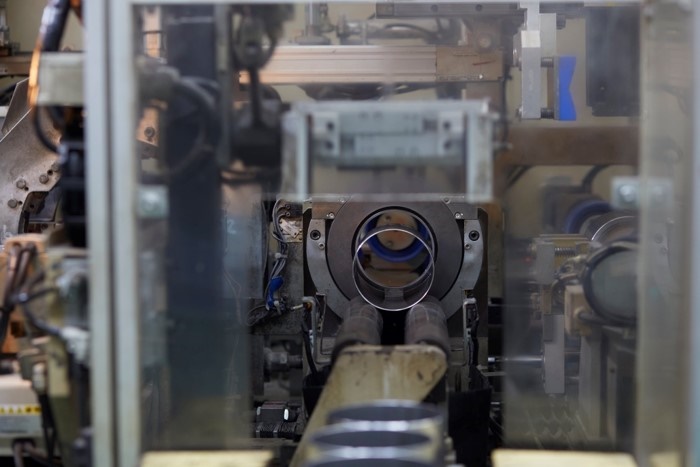

Caning Machine functions as an automatic catalytic exhaust filter assembly

Assemble Case with Catalytic applying modern technology

Intensive inspection process can ensure in every product produced